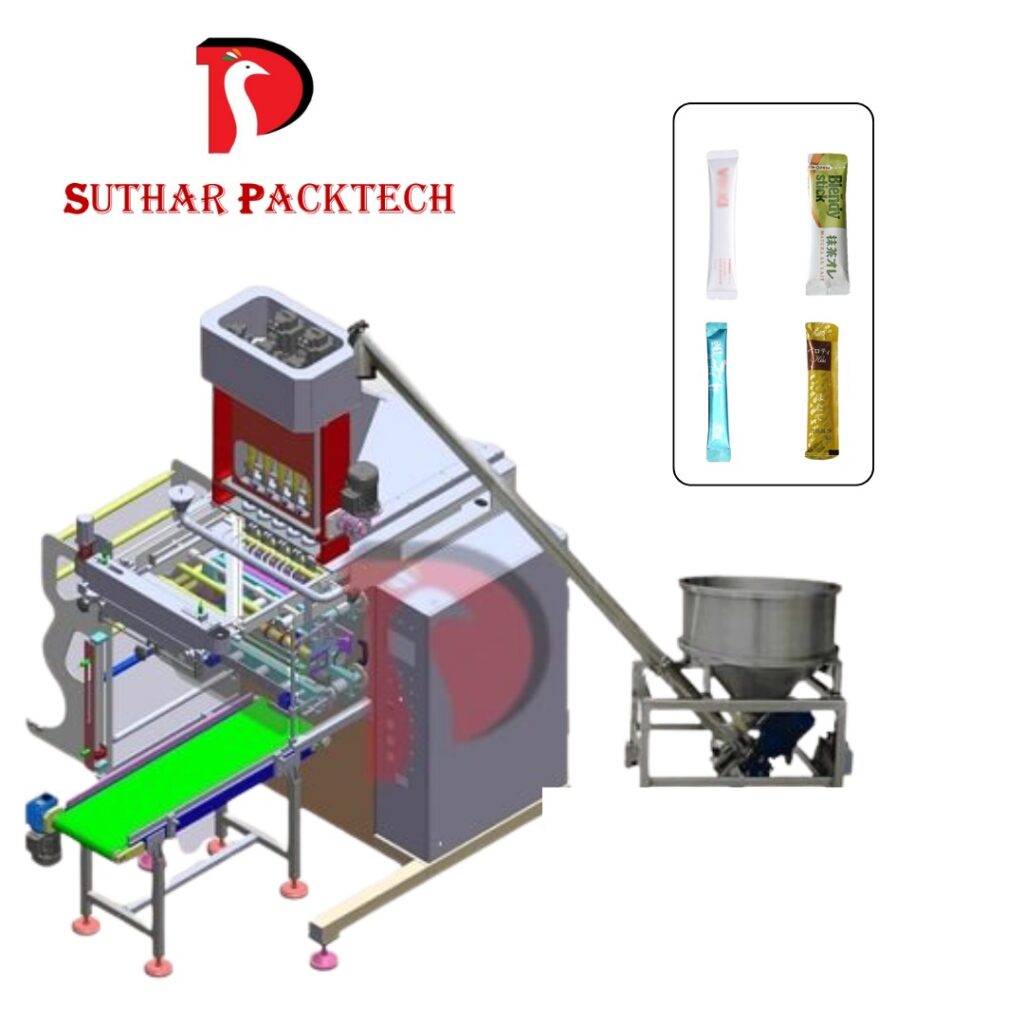

Stick Pack Machine - Perfect for Liquid, Coffee, and Powder Packaging Machinery

Features of Stick Pack Machine

- Fully programmable logic controller with HMI.

- No film alarm notifies the operator, thus minimizing film waste.

- Photocell tracking capabilities that achieve high precision.

- Easy support equipment integration.

- Quick tool-free changeover.

- Durable SS 316 stainless steel.

- Emergency stop, count capacity, and ready pack output.

- Powder, granules, or liquid filling capabilities.

Suthar Pack Tech, based in Faridabad, Haryana, is a leading manufacturer of stick pack machines. Renowned for their precision engineering and innovative designs, their machines offer efficient and reliable packaging solutions for various industries. Suthar Pack Tech creates high-quality, customizable machines that ensure precise dosing and seamless operation. Committed to customer satisfaction, they provide robust and durable packaging equipment that meets the highest industry standards. Choose Suthar Pack Tech for an advanced automatic stick pack machine that enhances production efficiency.

Our Products

Specifications of Stick Packaging Machine

- Machine weight can go up to 900 kg.

- A maximum film roll diameter of 320 mm.

- Maximum film width of 520 mm.

- Power needs are 220 V, and 50 Hz or 60 Hz, depending on your region.

- The number of lanes varies from 1 to 12.

- Back sealing or stick bag functionality.

- The air power is 0.8 MPa with 0.8m3/min.

Suthar Pack Tech, located in Faridabad, Haryana, is a renowned manufacturer of stick packaging machine. Specializing in high-quality, efficient, and reliable packaging solutions, they cater to diverse industries such as food, pharmaceuticals, and cosmetics. Their advanced machinery ensures precise and hygienic packaging of products in stick packs. With a commitment to innovation and customer satisfaction, Suthar Pack Tech has established itself as a trusted leader in the packaging industry. Choose Suthar Pack Tech for superior stick packaging solutions tailored to your needs.

Standard Features of Coffee Stick Packing Machine

- The multi lane coffee stick pack machine can automatically complete multi-lane product measuring, feeding, filling, bag forming, date code printing, bag sealing, and cutting. And hole punching as an option.

- Motor driven heat seal film pulling system.

- High sensitive fiber optic photo sensor can automatically trace color marks accurately.

- PLC control system combined with a touch screen, can easily set and change the packing parameters. Daily production output and self-diagnostic machine errors can be viewed directly from the screen.

- PID temperature controller monitors heat sealing temperature within ±1°C

Suthar Pack Tech, located in Faridabad, Haryana, specializes in manufacturing coffee stick packing machines. Renowned for their precision and efficiency, these machines ensure high-quality packaging, enhancing product shelf life and presentation. Trust Suthar Pack Tech for reliable and innovative packaging solutions.

Specifications of Sugar Stick Sachet Packing FFS Machine

- Most economical machine for automatic sugar stick packing requirement

- Specially designed one-piece former for easy and fast change over

- With digital temperature control system for perfect sealing

- With digital counter to count number of sachets produced by the machine

- All product contact parts are made up of Stainless Steel

- World class bought out items for optimum operations

- Designed to work 24 hours, round the clock

- Operator friendly machine, hence easy to operate and maintain

- Low maintenance and operating cost

- Sturdy design to ensure long life and trouble-free operation

The stick pack FFS machine used in pharmaceutical plants is designed to package pharmaceutical products such as tablets, capsules, powders, and liquids. The working principle of the FFS machine in a pharmaceutical plant involves the following steps:

- Film feeding: The stick pack FFS machine starts with a roll of packaging film that is unwound and fed through the machine.

- Forming: The packaging film is then formed into the desired package shape, such as a pouch or sachet, using a forming collar and a set of forming jaws.

- Filling: The pharmaceutical product is dispensed into the formed package using a filling mechanism such as a volumetric filler, a dosing pump, or a weighing scale.

- Sealing: Once the package is filled, the sealing process begins. The sealing jaws of the FFS machine come together and apply heat or pressure to the top and bottom of the package, sealing it shut.

- Cutting: The sealed package is then cut from the film roll using a cutting machine such as a rotary knife or a guillotine.

- Discharge: The completed package is discharged from the FFS machine for further processing, such as labeling, cartooning, or case packing.

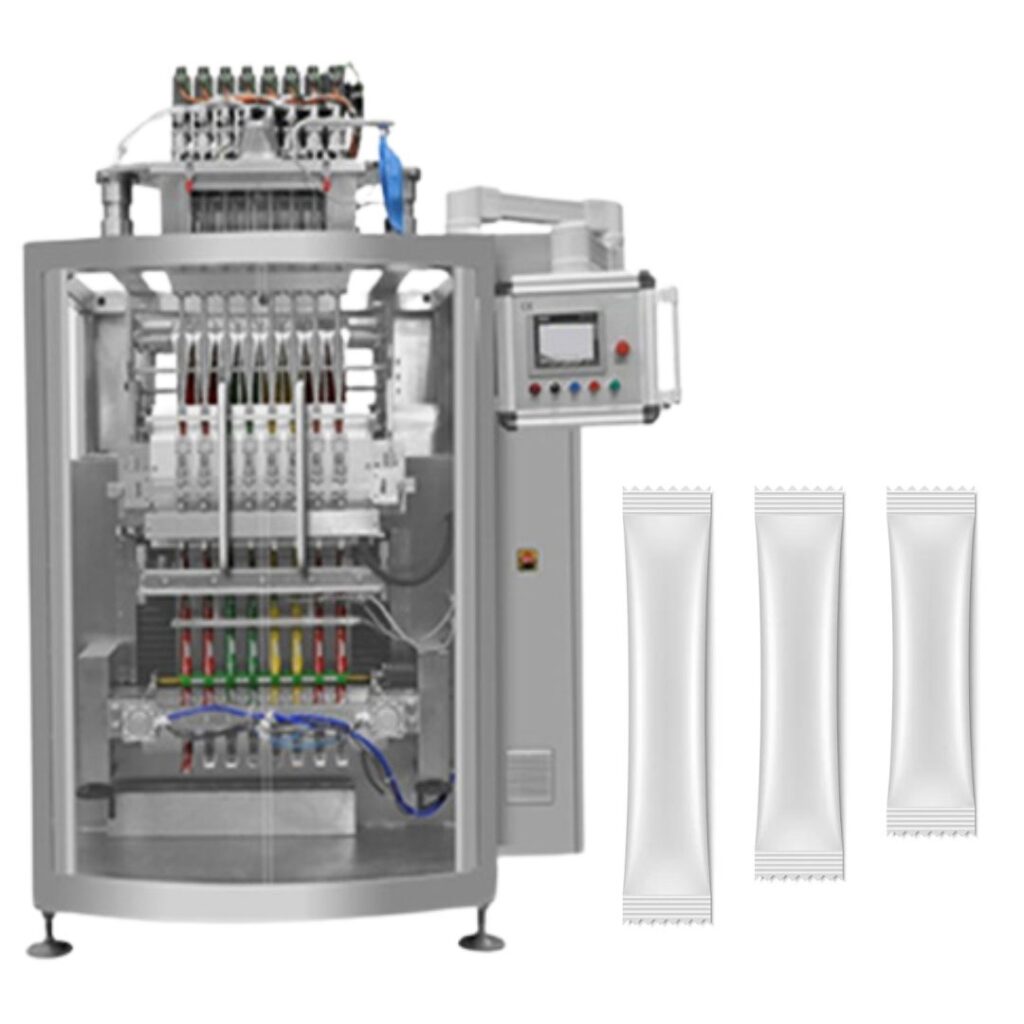

Features of Multilane Stick Pack Machine

- GMP construction.

- PLC based control system.

- 7″ Touch HMI.

- Powered film unwind.

- Film tension control.

- Photo eye for film length control.

- Auto web alignment.

Suthar Pack Tech, based in Faridabad, Haryana, is a renowned manufacturer of multilane stick pack machines. Specializing in innovative packaging solutions, Suthar Pack Tech’s machines are designed for high efficiency and precision in packaging granular, powder, and liquid products. With a focus on quality and reliability, their stick pack machines are ideal for various industries, ensuring consistent and efficient packaging. Trust Suthar Pack Tech for advanced, cost-effective stick pack solutions that enhance production capabilities.