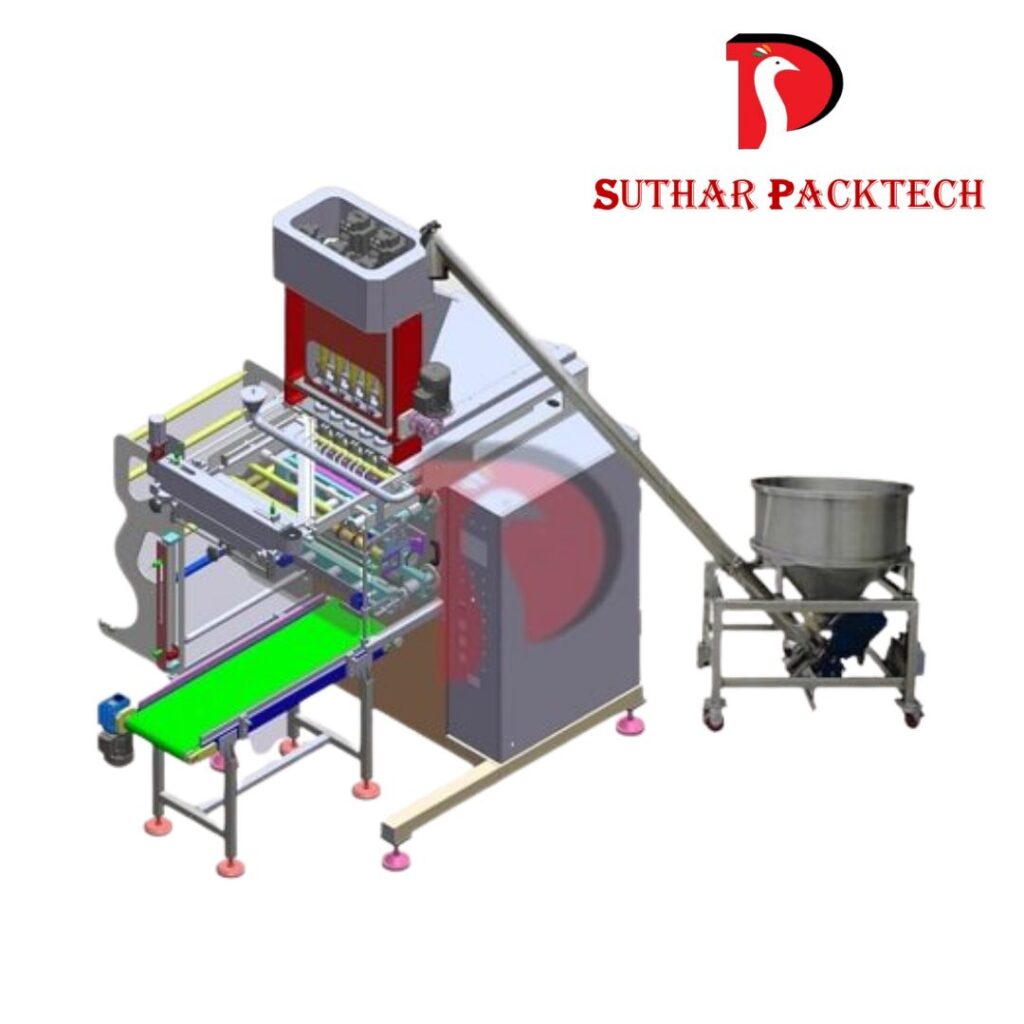

Stick Sachet Packing Machine

Features of Stick Sachet Packing Machine:

- PLC & 7 inch touch screen control,program is more flexible,specially customized for you.

- More safety guard and prevent wrong operation from injured .

- More intelligent , do not waste the film and with counting function .

- All machine body are made of stainless steel SS 304 .

- Various types of heating sealable laminated films can be run on the machine

Stick Sachet Packaging Machine Manufacturer

Features of Stick Sachet Packing Machine:

- PLC & 7 inch touch screen control,program is more flexible,specially customized for you.

- More safety guard and prevent wrong operation from injured .

- More intelligent , do not waste the film and with counting function .

- All machine body are made of stainless steel SS 304 .

- Various types of heating sealable laminated films can be run on the machine

Our Products

FAQ's

A sachet packing machine is designed to efficiently package products into compact, sealed pouches. Ideal for food, pharmaceuticals, and cosmetics, this machine streamlines the process by forming, filling, and sealing sachets in one seamless operation, ensuring precise, hygienic packaging of single-serving or portion-sized items.

A sachet packing machine works through a series of steps to efficiently package products into small, sealed pouches. Here’s a basic overview of the process:

Film Unwinding: The machine uses a roll of packaging film that is unwound and fed into the machine.

Forming the Sachet: The film is then drawn through a forming section where it is shaped into the desired sachet form, typically involving folding and sealing the film to create a pouch.

Filling: The machine dispenses the product (e.g., powder, liquid, or granules) into the formed sachets. This is done using a filling system that measures and fills precise quantities.

Sealing: After filling, the sachets are sealed using heat or ultrasonic technology. This step involves sealing the top and bottom of the sachet to ensure it is airtight and secure.

Cutting and Dispensing: Finally, the machine cuts the filled and sealed pouches from the continuous film and dispenses them for packaging or further processing.

A sachet packing machine can pack a wide variety of products, including:

Food Products: Powders (like coffee, tea, and spices), granular items (such as sugar or salt), and liquids (such as sauces, condiments, and soups).

Pharmaceuticals: Single doses of medications, vitamins, and dietary supplements.

Cosmetics and Personal Care: Single-use samples of creams, lotions, shampoos, and conditioners.

Household Products: Detergents, cleaning powders, and other household chemicals.

Agricultural Products: Seeds, fertilizers, and pesticides.

Industrial Products: Lubricants, additives, and other small, controlled-quantity substances.

When choosing a sachet packing machine, consider the following factors to ensure it meets your needs:

Product Type: Ensure the machine can handle the specific type of product you plan to pack, whether it’s powder, liquid, granules, or a combination.

Pouch Size and Shape: Verify that the machine can accommodate the size and shape of the sachets you require, including variations in dimensions and formats.

Production Speed: Consider the machine’s speed and throughput to ensure it aligns with your production requirements. Higher speeds may be necessary for larger volumes.

Accuracy and Precision: Evaluate the machine’s ability to accurately fill and seal sachets, ensuring minimal waste and consistent quality.

Ease of Use: Look for user-friendly controls and features, such as an intuitive interface and easy adjustment settings, for efficient operation and maintenance.

Material Compatibility: Check that the machine supports the type of packaging film or material you plan to use, including options for different film types and thicknesses.

Hygiene and Cleaning: Consider the machine’s design in terms of ease of cleaning and maintenance, especially if you’re packing food or pharmaceutical products.

Automation and Integration: Evaluate the level of automation and whether the machine can integrate with other equipment in your production line for streamlined operations.

Cost and Budget: Balance the cost of the machine with your budget and the expected return on investment. Consider both the initial purchase price and ongoing operational costs.

Service and Support: Ensure the manufacturer or supplier offers reliable support and service, including training, maintenance, and spare parts.

Compliance and Certifications: Verify that the machine meets industry standards and regulations for quality, safety, and hygiene specific to your sector.

- Increases Efficiency: Packs faster than manual methods, boosting production speed.

- Ensures Consistency: Delivers uniform pouch size and fill every time.

- Reduces Costs: Lowers labor costs and improves overall cost efficiency.

- Improves Hygiene: Minimizes human contact, reducing contamination risks.

- Enhances Brand Image: Provides professional, attractive packaging.

- Supports Growth: Scales with your business as demand increases.